Products & Services

Pressure Vessels (Heat Exchangers/Towers, Vessels and Reactors)

Teijin Engineering designs, manufactures and installs heat exchangers, towers, vessels and tanks used by petroleum refineries, petrochemical plants and other similar facilities.

In addition, Teijin Engineering is the only company in Japan capable of analyzing and manufacturing DTS, an indispensable technology when it comes to tube vibration prevention for heat exchangers.

In addition, Teijin Engineering is the only company in Japan capable of analyzing and manufacturing DTS, an indispensable technology when it comes to tube vibration prevention for heat exchangers.

Products

Heat Exchangers

- Shell and tube heat exchangers

- Double tube-type heat exchangers

- LNG/ammonia vaporizers

- Hairpin-type heat exchangers

- Feed water heaters

Towers, Vessels and Reactors

- Distillation towers

- Agitated vessels

- Reaction towers

- Accumulators

- Absorption towers

- Cone roof tanks

Features

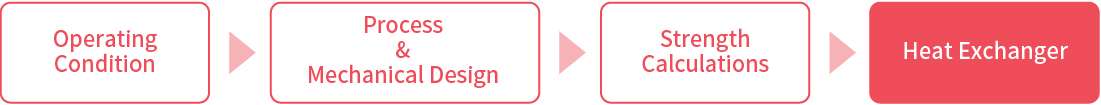

Heat Exchangers

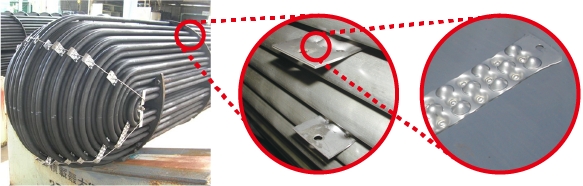

DTS

DTS(Dimpled Tube Support)

By inserting DTS (STS*) dimpled and corrugated metal strips in between tubes, vibrations are suppressed and the tube bundle is strengthened.

※STS(Saddled Tube Support Technology) …effective with soft metal finned tubes.

- Can be easily installed in existing bundles

- Capable of eliminating tube vibration noise

- Increases the natural frequency of the tubes to lessen vibration

- Able to be used in U-bend sections as well

Compatible with a wide range of laws and regulations,including the Industrial Safety and Health Act and the High Pressure Gas Safety Act

Japanese Regulation

- Industrial Safety and Health Act (Boilers, Class-1 Pressure Vessels, Class-2 Pressure Vessels, Small-size Boilers,Small-size Pressure Vessels)

- High Pressure Gas Safety Act(Specified Equipment Inspection Regulations, Refrigeration Safety Regulations)

- Electricity Business Act (Process I certified welding factories)

- Gas Business Act

Able to manufacture a diverse array of chemical engineering equipment in specialized materials

Materials H andled

- Stainless steel (austenitic, ferritic, martensitic, duplet)

- Low alloy steel (such as SCMV3)

- Copper alloy (C1220, C4430, C6872, C7150, etc.)

- Nickel alloy (NCF600, NCF825, hastelloy, carpenter, etc.)

- Titanium alloy (such as TTH340W)

- Various clad steel(SB410 + C6161P,SCMV3 + SUS405, SB410 + TP340, etc.)

- Other (HIC-resistant SB410, SN-5, SUS444, etc.)

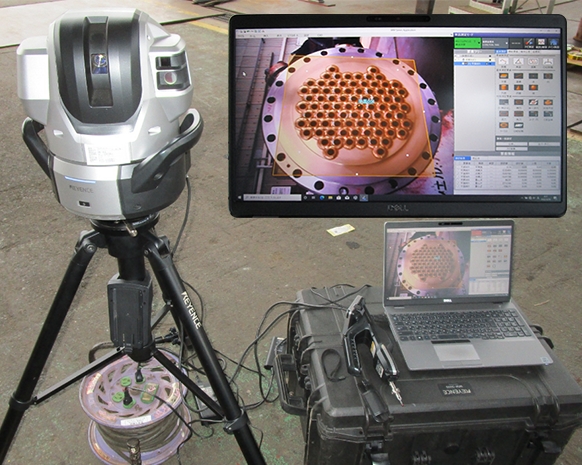

Can accommodate projects with tight deadlines which require maintenance technology specific to heat exchangers

We can undertake on-site work, as well as off-site work at our factories such as repairing existing equipment including re-tubing, measuring sheet surface distortion, and surface repair. Whether it is a regular or unexpected job, we ensure the shortest turnout time possible depending on the situation.

Heat exchanger equipment

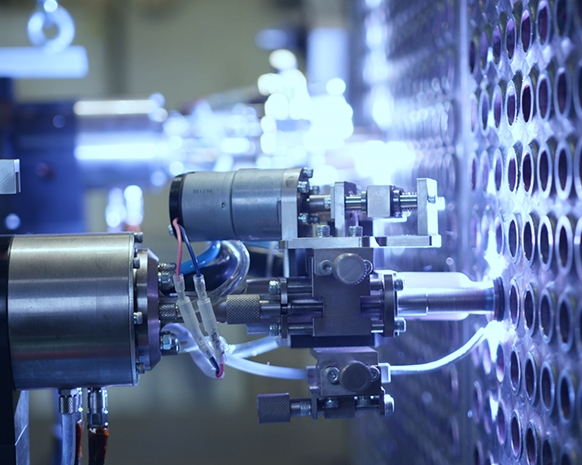

For higher levels of automation

Aiming for advanced quality

Inquiry about Pressure Vessels (Heat Exchangers/Towers, Vessels and Reactors)