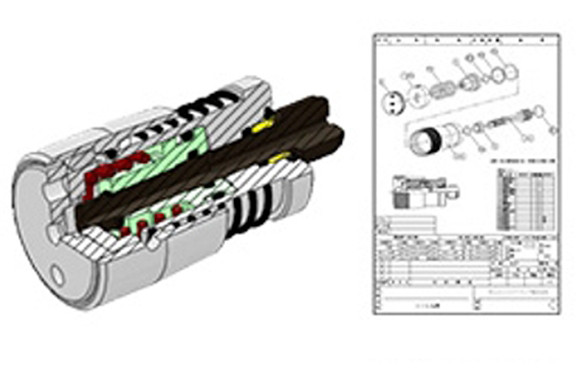

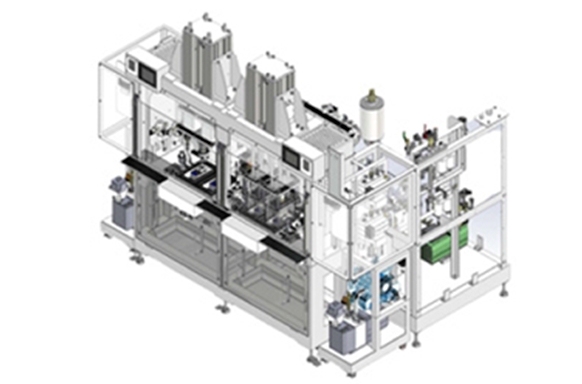

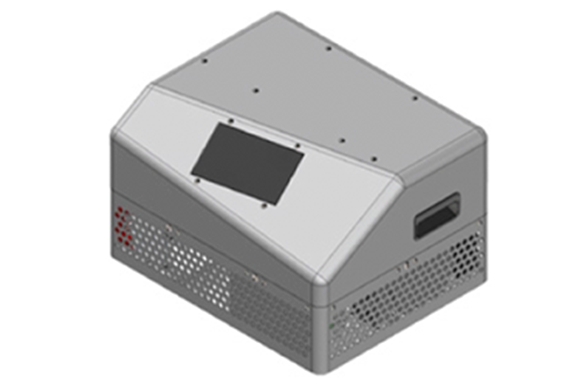

Leakage Inspection System (Helium gas/Helium gas collect device/Argon gas)

This system measures the leakage of a given product by injecting it with helium gas and then measuring the amount which leaks out.

Features of helium gas airtightness inspection equipment

-

1.

High accuracy/high reproducibility : Approximately 1000 times higher resolution than submersion method and air differential pressure method.

-

2.

Short inspection time : Diffusion speed is fast, so inspection time is reduced by about 75% compared to the air differential pressure method.

-

3.

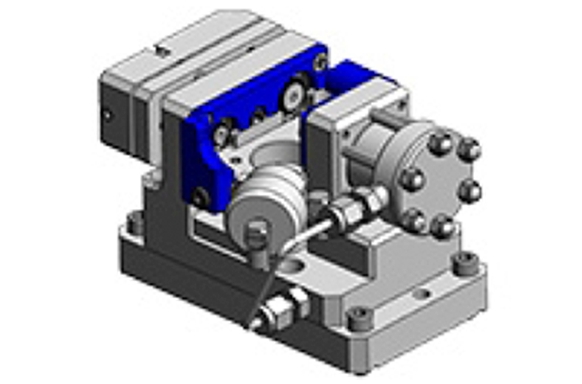

Customization of airtight jig : Design and manufacture of special airtight automatic sealing jigs according to products.

Features of argon gas airtightness inspection equipment

-

1.

High accuracy/high reproducibility : Approximately 1000 times higher resolution than the submersion method and the air differential pressure method, similar to the helium gas method.

-

2.

Gas characteristics : Due to the characteristics of argon gas, it does not permeate or absorb compared to helium, so recovery is quick and continuous inspection is possible.

-

3.

Inspection of resin products : Argon gas has no absorbency, so it is possible to inspect resin-based products that were difficult to inspect with helium gas.

-

4.

Low running cost : Argon gas can be supplied stably, so the running cost is much lower than that of helium gas.

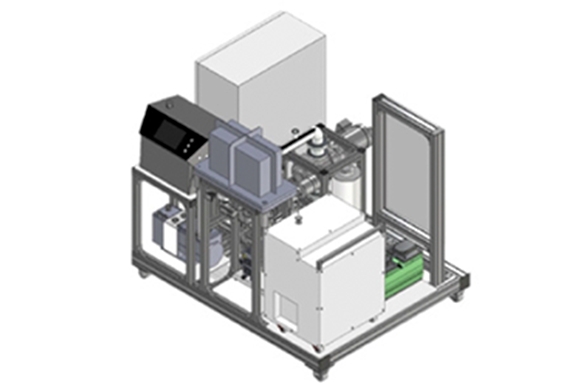

Helium gas collect device

-

1.

High collect rate : A high collect rate (98% or more) is achieved because helium gas is collected in the negative pressure region.

-

2.

Supports various boosters : Boosters such as electric compressors and air-driven boosters can be installed (up to 100MPa).

-

3.

Customizable according to recovery specifications. : We offer total solutions through customization to your recovery specifications.